Protecting Vision, Defining Style

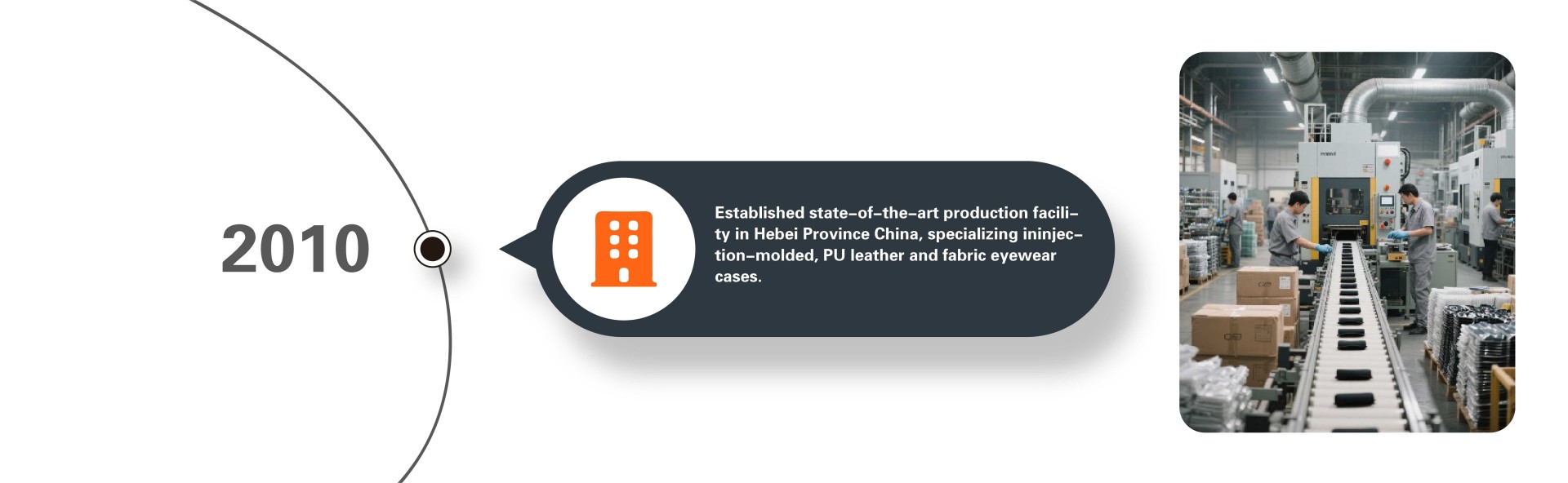

Established in 2006 with our proprietary production base, we have evolved from a local manufacturer into a globally recognized specialist in eyewear case solutions.

Combining precision engineering with sustainable innovation, we deliver protective solutions that seamlessly integrate functionality and elegance for international brands.

🏭 Advanced Manufacturing:

32 injection molding machines with IoT monitoring for micron-level precision.

🔬 R&D Excellence:

Dedicated lab for material stress tests and 10,000+ cycle durability trials.

👥 Expert Leadership:

20-year industry veterans holding ISO 9001 & BSCI certifications.

Our Journey

Our Vision

To redefine global standards for protective eyewear solutions through sustainable engineering excellence. We pioneer intelligent, eco-responsible case designs that empower brands to elevate user experiences while advancing circular economy principles worldwide.

Our Mission

To engineer precision-protective eyewear solutions through sustainable innovation, empowering global brands to merge elegance with environmental responsibility.

FAQ

How to choose the size of glasses case? Can I put down my sunglasses/frame?

Optical glasses: Choose a box with an inner length of ≥ 150mm and a width of ≥ 55mm (regular rectangular style)

Sunglasses/Pilot Style: Inner length ≥ 160mm, width ≥ 70mm (elliptical or widened design is recommended)

Practical suggestion: Measure the maximum length of the mirror legs after unfolding, and add a margin of 10mm as the safe value.

What material is? the most durable Is the soft leather glasses case really pressure resistant?

|Material type | Advantages | Disadvantages | Applicable scenarios|

|————–|———-|———-|————–|

|Hard (wood/metal) | Strong compression resistance, high-end texture | Heavy weight, high price | Home storage, luxury glasses|

|Soft material (PU leather/nylon) | Lightweight, foldable | Moderate collision resistance | Daily commuting, portable|

|New materials (plastic steel/acetate fiber) | Corrosion resistant, bright colors | High temperature deformation | Fashionable matching, suitable for teenagers to use|

Key reminder: Choose a velvet lined hard box to avoid scratching the lenses; The tightness of the stitching needs to be confirmed for the soft box.

Do you have a contact lens case with care reminder?

WiFi networking reminder for changing care solution deadline (to prevent eye infections)

What should I do if the lenses are always scratched in the box? Do glasses cases need to be cleaned?

Key points for scratch prevention

Place the lens facing upwards to avoid contact with the bottom of the box

Priority should be given to folding the mirror legs inward to prevent damage from external forces

Cleaning standards

Hard box: wipe the inner lining with alcohol swabs once a month

Contact lens case: Replace every 3 months, boil and disinfect for ≤ 10 minutes

Can I engrave/print a logo?

We offer logo customization services, with a minimum order quantity of just 1 unit. Simply provide us with your logo, and we’ll promptly create a rendering for your approval on the logo’s size. Upon your confirmation of the size, we’ll proceed with producing the product based on the approved rendering.

What types of logos can be customized for eyeglass cases?

We can craft any pattern or logo you desire onto paper, PU leather, or fabric.

Typically, our logo options encompass embossed, debossed, single-color silk screening, dye sublimation, full-color printing, multi-color silk screening, UV printing, black hot stamping, silver hot stamping, and golden hot stamping. For specific effect images, please reach out to our sales team.

Can I get samples or trial order?

Of course, our samples are complimentary. All you need to cover is the shipping cost to your country. However, if you have a delivery address in China, our samples are entirely free of charge, and you won’t even have to bear the shipping expenses.